I have been an independent product design consultant from 1978 to my retirement in 2014.

Over that period I provided quality mechanical engineering, electronic packaging and

project management services for new products in internet electronics, commercial

electronics, and medical devices. Clients benefitted from my early background as a stress

analyst, my eye for detail, and knack for creating products that are easily fabricated,

assembled and serviced. Working closely with each client's staff, I treated the vital issues of

structure, component placement, wiring, cooling, EMI/RFI isolation, manufacturability, and

user ergonomics to ensure well-integrated products.

Here is a sampling of career projects...

Solea Dental Laser by Convergent Dental of Natick, MA, is the first CO2 laser to be

cleared by the FDA for hard, soft, and osseous tissue procedures, virtually eliminating

anesthesia and blood from operative dentistry. The dentist saves time... no injections,

no waiting. They can work in multiple quadrants, address cavities discovered during cleaning

in the same appointment, and do many soft tissue procedures directly. Because of its

unique computer controls, patients experience no vibration, no noise, no numb jaw.

Brought to market in mid 2013, this device has the potential to change the way dentistry

is practiced... worldwide!

My primary responsibilities were to create the wheeled cart that houses the laser and its

optical, electronic, and pneumatic components. With excellent coordination from

electronics consultant Bill Groves of Sachem Design and from members of the Convergent

Dental design team, I grouped components into modules for assembly inside a sheet metal

structure, shielded the electronics for interference, and established a cooling scheme.

Industrial designer Hern Kim of Hernetics, LLC joined me to shape the overall design with

pressure-formed panels that met the aesthetic and ergonomic requirements of this chair-side

device.

The intense two-year team effort that created this highly acclaimed dental instrument

also yielded several major awards:

- Medical Design Excellence Award - Gold, best dental instrument or product - 2014

- Dr. Bicuspid Award - Best dental product of the year - 2014

- Popular Science - "top 100, best of what's new" Award - 2014

- Edison Award - Gold winner for Innovation - 2015

- PRISM Award - Finalist - 2016

(http://www.convergentdental.com/solea/)

Song Meter SM3 is an advanced professional bioacoustics recorder by Wildlife Acoustics

of Concord, MA. Its cast aluminum enclosure is fully sealed and ruggedized for reliable

wildlife field recordings of up to 260 hours. This device allows you to simultaneously

record any combination of avian, terrestrial, herpetological and marine life. In a project

led by Origin Product Development of Maynard, MA, my role was to create accurate 3D CAD

models of the physical components and to collaborate on the design and layout of the

enclosure. We focused on designing water-tight seals everywhere, optimizing the internal

wiring for manufacturing assembly, ensuring robust component mounting against major

impact and vibratory loads, and providing improved enclosure field mounting options.

(

http://www.wildlifeacoustics.com/products/song-meter-sm3)

Sanitaire Gold Series Diffuser by Xylem is a fine bubble aeration system with superior energy

efficiency for water treatment plants. This Diffuser delivers high standard oxygen transfer

efficiency (SOTE) while minimizing system head loss. Its modular design facilitates installation

and retrofit. The combination of high density configurations and low flux enables the highest

possible oxygen transfer utilizing the least possible energy. I was involved with the conceptual

redesign of the Diffuser, helping create the unique membrane long-edge clamping system and

the basics of the narrow end clamping mechanism. US Patent 8002249

(

http://www.xylem.com/treatment/at/products/gold-series-membrane-diffusers)

Early Alzheimer's Disease Detection System by Cognoptix is a simple, innovative non-invasive

eye-scanning test. I assisted the company staff with rapid mechanical enhancements to the

original prototype. Their newest Sapphire II device is expected to permit early diagnosis with an

eye test at the point of care. (

http://www.cognoptix.com/)

Cell Separation Apparatus by Endocellutions for isolating a fraction of interest from a

physiological fluid sample. One application is stem cell isolation and. My role was to help

design a prototype device suitable for high-volume injection molding. US Patent 8241592

(

http://endocellutions.com/)

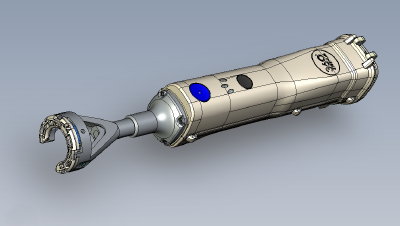

SuturTek's 360° Sternum Closure Device

TM eliminates

the difficulty and danger of closing the sternum manually with the simple push

of a button. (Image at left.) A steam-sterilized outer handle seals a removable

battery-powered motor module inside. The surgeon snaps a sterile needle cartridge

onto the front end, positions the device against the sternum and presses a button

to drive a standard needle with attached sternal wire cleanly through.

(

http://www.suturtek.com/SC/)

Abiomed's AB5000

TM Circulatory Support System provides

temporary support for one or both sides of the natural heart in circumstances

where the heart has failed, giving the patient's heart the opportunity to rest and

potentially recover. (Image at right.) This complex battery-backed-up electronics

device is constructed of sheet metal and machined parts with plastic skins,

over-molded metal and cast urethane parts. The AB 5000 passed the severe helicopter

transport and UL medical equipment tests on the first try. This was the second

consecutive generation of this product we were hired to design. Industrial design

and project lead by Michael Cattafe, Origin Product Development.

(

http://www.originpd.com/)

A small battery-powered Smart-MagnetTM for Medtronic Inc.

providing safe management of patients' ICD devices during surgical procedures.

(Image at left.) Despite the heavy internal permanent magnet, our injection-molded

enclosure exceeded all requirements for multiple drops to the operating room floor.

Generations of electronic Holter Recorders for Northeast Monitoring Inc. Each

new model reduced overall size while improving ruggedness. (Image at right.)

(Mark Hubelbank, a founder, is my oldest continuous client; we first worked

together on a heart monitoring product in 1983.)

(

http://www.nemon.com/)

Prototype body-worn biosensors for a variety of FitSense Technologies Inc. RF-linked

devices, since 1998.

(See more at

http://www.fitsense.com/)

AirMotion Sciences has developed a new HVLS (high volume - low

speed) fan to help solve air movement, energy cost, and facility

temperature and air quality problems. (Image at left.) Using Variable

Pitch Technology

TM, Rotatair

TM molded blades and custom

electronics, this new breed of large ceiling fan improves the comfort

of facility environments while providing immediate cost benefits and

savings. This fan moves massive amounts of air efficiently with low

power consumption, letting people (or animals) below be more comfortable

while lowering other conditioned air requirements.

(

http://www.airmotionsciences.com/)

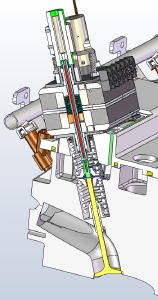

Engineering Matters, Inc. has developed a fully flexible EVA

(electromagnetic valve actuator) that replaces conventional belt-driven cam

actuators in internal combustion engines and deliver a 20% improvement in

fuel economy, 20% reduction in emissions, and improved low end torque.

(Image at right.) This patented and patent-pending design allows for

fully flexible valve control variable timing and lift and low valve landing

speed. The camless EVA applies to spark-ignition, compression-ignition, and

homogenous-charge-compression-ignition (HCCI) engines for optimum operating

performance. Presented as Paper 2008-01-1350 at the SAE International World

Congress in Detroit, April 14-17, 2008, the EVA won an

R&D 100

award for 2008.

(

http://engineeringmatters.com/

and select "Projects").

A line of force feedback joysticks for Engineering Matters, Inc. that required

careful attention to manufacturing technology costs, understanding of the

electromagnetic forces so a proper structural support system could be

designed, and accurate mechanical assembly. (Image at left.)

One direct drive joystick won an

R&D 100 award for

being one of the 100 most technologically significant products introduced into

the marketplace in 2005. US Patent 20040027332

(

http://www.engineeringmatters.com/)

AS&E's BodySearch

TM enclosure for their backscatter

contraband detection system which detects items hidden in or under people's clothing.

Designed in 1995, next generations of this system are in wider use today.

(

http://www.as-e.com/)

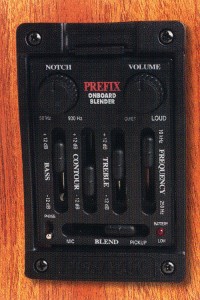

Fishman Transducers' onboard "Prefix" preamp system that blends music

pickups in acoustic guitars. An injection-molded outer

bezel-and-inner plate pair, loaded with electronics, mount in

the side of acoustic guitars and provide a patented flip-up

access to its 9-volt battery. The challenge was to design the

outer bezel to flex sufficiently to fit the side contours of

most any guitar while latching securely without vibration.

Depending on the guitar model, the mounting contour might be a

convex surface, a concave surface, or an s-curved surface.

The successful solution required a custom plastic formulation

and a special latch design.

Fishman Transducers' Acoustic Performer Pro and Acoustic

Monitor one-piece 230 watt amplifiers. Both these compact

high performance systems deliver crisp, clear sound with

unmatched versatility and portability. The rugged

roto-molded plastic cabinet was designed to stand upright,

lie on an angle to act as a monitor, or be set up on a

stand. All controls are safely recessed and a built-in hand

grip eases portage of its 29 lb weight.

Various enclosures for the networking startups of Brix Networks, AmberWave (sold to US

Robotics/3COM in 1996), NetICs (sold to Bay Networks/Nortel in 1996), plus major

cost-reduction for Nashoba Networks (sold to Cisco Systems in 1996), two

projects for Prominet Corp (sold to Lucent in 1997), and multiple projects

for New Oak Communications (sold to Bay Networks/Nortel in 1998).

PixelVision's color flat panel systems, often with integrated touch sensors and

X-terminals or embedded PCs in thin (under 3.75") packages. In 1993, we designed

the first generation of these space-efficient systems that were hung on overhead arms

at the New York Stock Exchange trading floor.

(You see similar units today on nightly business reports.)

The Trotter 645/640 treadmill series for high-volume manufacturing with improved

modularity for lower cost, ease of assembly, and servicing. Major parts were designed

in sheet metal, structural foam and tubular steel weldments.

A custom laboratory equipment cart for PerkinElmer Life and Analytical

Sciences that exactly meets the rigidity, ventilation, and ease of

component servicing requirements for their precision tabletop devices.

(Image at right.)

Leaf System's LeafaxTM, the world's first

portable 35mm electronic darkroom, which revolutionized the worldwide

photojournalism industry in 1988. Well before today's digital cameras,

it combined a precision 1200 dpi line scanner, custom electronics,

keyboard, monitor and fax modem in an attache case, with key parts injection

molded for lower cost, parts consolidation, and weight reduction.

My 1500 square foot office in Acton houses a

conference room, design area, and model shop.

I use SolidWorks 3D solid modeling software which allows me to

communicate and coordinate concept images and technical design

data with anyone, anywhere. I am a member of the SolidWorks

Manufacturing Network.

From 1968 to 1978, I was employed in engineering analysis and design positions

at Magnetic Corporation of America, BLH Electronics, Teledyne Engineering

Services, and Knolls Atomic Power Laboratory. My degrees are a B.S. in

Mechanical Engineering from Union College 1966 Schenectady, NY, and a Master of

Engineering from The Pennsylvania State University 1968 College Park, PA.